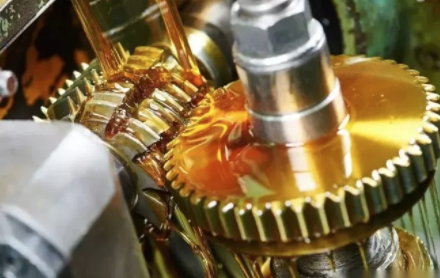

Nowadays, with the continuous advancement of industrialization, plastic gear transmission has become the most widely used transmission method in the application of mechanical transmission parts. Because of its light weight, low transmission noise, high temperature resistance of gears, and increasing ability to withstand high loads, it is more and more widely used in various fields.…

Although molybdenum disulfide grease and graphite grease are black grease from the appearance,we can not judge the grease product from the appearance alone, it is necessary to analyze the difference between the two from their physical properties. Both molybdenum disulfide and graphite are high temperature resistant solid additives, but they are different. 1.Molybdenum disulfide grease…

What is molybdenum disulfide ? Molybdenum disulfide is a solid surface lubricant, its main role is wear resistance, lubrication, corrosion. The temperature range is generally from-200 ° C to 400 ° C, which has high bearing capacity and is suitable for low speed and heavy load friction lubrication. What is the role of molybdenum disulfide…

High temperature grease is a special kind of grease, which requires high lubricity, high temperature resistance and durability. It is recommended to use synthetic base oil to produce grease with uniform and stable oil film. Due to the increasingly harsh working environment of mechanical equipment, the demand for grease is also increasing. But in some…

This article will tell you the performance characteristics and advantages of semi-fluid grease in detail. Semi-fluid grease refers to the general term of grease with consistency in the range of 000 ~ 0. Semi-fluid grease is only for ‘ hardness ‘, not for other quality indicators or product types. The state of semi-fluid grease is…

The editor of the previous issue introduced the composition and main functions of bearing grease. This issue will then introduce in detail how to select bearing grease. Different bearings require different greases, and the greases used under different working conditions are also different. When selecting greases, we should consider the following factors : 1. temperature…

·Bearing grease-bearing service life of the ‘ blood ‘ * * Bearing grease is a widely used lubricant.It is often used in bearing repair and maintenance to ensure the normal operation of the running parts of the equipment. It is also an important factor affecting bearing life. Bearing grease consists of base oil, additives, and…

1.Excessive bearing grease will not only fail to lubricate, but also have many negative effects. – – Taking bearings as an example,add excessive bearing grease, which will lead to increased bearing rotation resistance, increased temperature and energy consumption, and increased temperature will also cause grease oxidation,Speed up ( early deterioration, oil service life is shortened…

Submit Request